Description

FLIR Muvetm C360 Chemical Hazards Detect

- Equipped with state-of-the-art sensors, this system accurately identifies toxic industrial chemicals (TICs) and volatile organic compounds (VOCs). As a result, it provides emergency response teams with instant situational awareness.

- Moreover, it uses advanced laser-based TDLAS technology to deliver highly selective gas detection. At the same time, it minimizes false alarms, improving overall operational reliability.

- Designed specifically for first responders, industrial safety teams, and environmental monitoring professionals, this solution supports remote inspections in high-risk environments.

- In addition, its lightweight and weather-resistant design allows reliable operation across various challenging outdoor conditions.

- Furthermore, the system offers real-time monitoring, which ensures rapid decision-making during critical missions. Consequently, it reduces personnel exposure to hazardous substances.

- Not only that, but the MUVE™ C360 also includes built-in data logging and reporting capabilities. Therefore, users can perform post-mission analysis for regulatory compliance and long-term risk assessment.

- With its fast response time, high sensitivity, and drone compatibility, the system delivers outstanding performance in demanding field conditions.

- Ultimately, the FLIR MUVE™ C360 is transforming the way teams handle gas detection and pollution control in today’s complex environments.

Feature |

Description |

|---|---|

| Remote Chemical Detection | Identifies hazardous gases and pollutants from a distance. |

| High Sensitivity | Detects gases with ppm accuracy. |

| UAV Integration | Compatible with DJI Matrice series drones. |

| TDLAS Technology | Reduces false alarms by ensuring selective detection. |

| Real-Time Monitoring | Displays live chemical concentration readings. |

| Compact & Lightweight | Optimized for drone mounting without affecting performance. |

| Data Logging & Reporting | Captures detection records for analysis. |

| Weather-Resistant | Functions effectively in various environmental conditions. |

| Fast Response Time | Detects leaks and pollutants within seconds. |

| Enhanced Safety | Allows remote hazardous gas detection, ensuring personnel safety. |

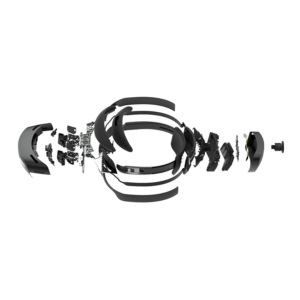

Key Components

-

FLIR MUVE™ C360 sensor module

-

High-precision TDLAS-based detection unit

-

Wireless real-time monitoring system

-

Data storage and logging system

-

Compact drone-mountable housing

-

Weather-resistant enclosure for outdoor operations

-

- Display & Alerts

- FLIR VueLink™ application integrated via tablet connected to the UAS remote controller

Сompatible with DJI Matrice 210, V1 and V2, M300RTK M200 series

Real-time detection

<30 mins for operator; 4 hours for advanced user

CO, Cl2, O2, NO2, H2S, SO2, LEL

VOC 10.6 eV (ppm)

1.5 lb (680.39 g) – C360 with dock and snorkel

Specification |

Details |

|---|---|

| Detection Range | Up to 100 meters |

| Gas Detection | TICs, VOCs, methane, and other hazardous gases |

| Sensor Type | Laser-based TDLAS technology |

| Response Time | Instantaneous (within seconds) |

| Drone Compatibility | DJI Matrice Series |

| Weight | Lightweight for UAV mounting |

| Power Supply | Rechargeable battery-powered |

| Weather Protection | Operates in various environmental conditions |

| Data Storage | Built-in logging for post-mission analysis |

| Connectivity | Wireless, real-time data streaming |

Includes

FLIR MUVE™ C360 sensor module

UAV mounting brackets

Rechargeable battery pack

Wireless connectivity system

Data logging software

User manual & installation guide

FAQS

- What gases can the FLIR MUVE™ C360 detect?

To begin with, the system detects toxic industrial chemicals (TICs), volatile organic compounds (VOCs), methane, and other hazardous gases with high accuracy. - Is it compatible with drones?

Yes, absolutely. The MUVE™ C360 is optimized for integration with the DJI Matrice series and other UAVs. - How far can it detect gas leaks?

Depending on environmental conditions, it can detect gases from up to 100 meters away. - What is the response time?

Impressively, the MUVE™ C360 provides instantaneous detection within seconds. - Does it provide real-time monitoring?

Yes, indeed. The system offers live chemical concentration readings and alerts. - Is it weather-resistant?

Certainly. The weatherproof design allows for outdoor operation in various conditions. - Can it log data for analysis?

Yes, of course. The system includes built-in data storage for post-mission reporting. - How does TDLAS technology improve detection?

In short, TDLAS (Tunable Diode Laser Absorption Spectroscopy) ensures high selectivity, reducing false alarms from other gases. - Who can benefit from using this system?

In practice, first responders, industrial safety teams, environmental monitoring agencies, and hazardous material detection units all benefit from using this system. - How is it powered?

Finally, it runs on a rechargeable battery with efficient energy consumption.

There are no reviews yet.