Description

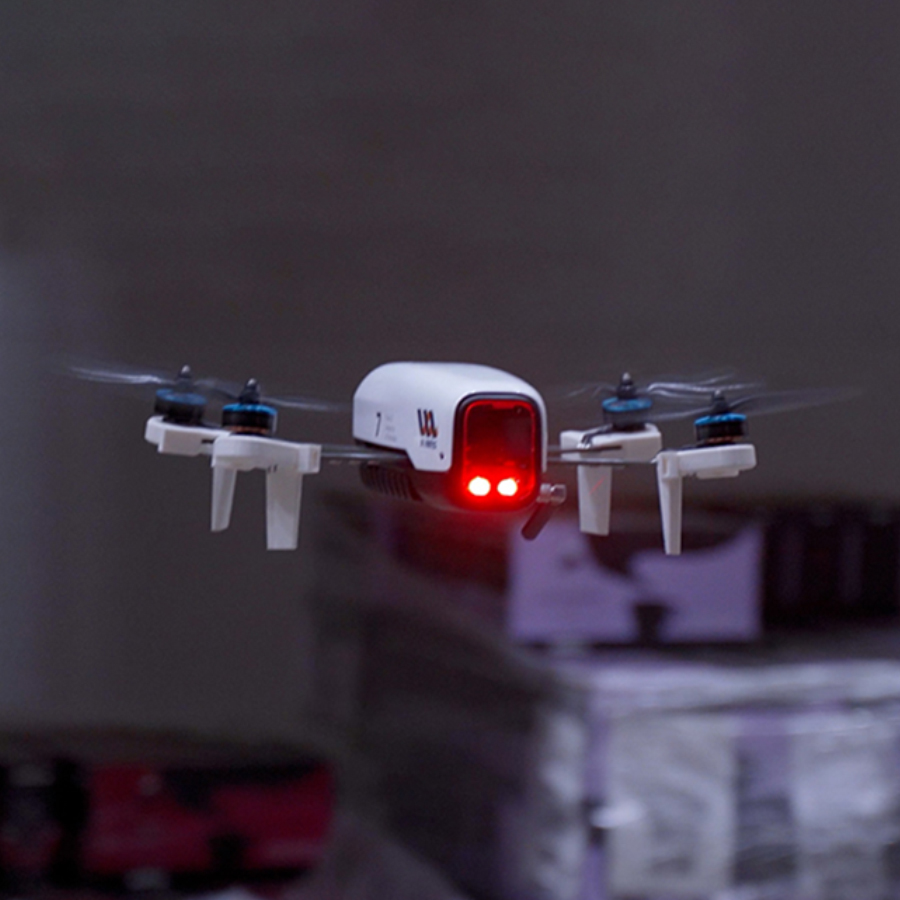

Introducing the UVL Inventory Management Drone

UVL Robotics has transformed inventory management by introducing an advanced warehouse inventory service that utilizes autonomous smart drones. This innovative solution offers a superior alternative to traditional manual stock management methods, delivering unparalleled efficiency, accuracy, and security. By significantly reducing the need for human involvement in inventory counts, it minimizes errors and enhances process efficiency by up to 50 times. The system enables instant data transmission to clients’ ERP systems, empowering businesses with the insights needed to make informed decisions and optimize warehouse operations. The drones operate autonomously, sequentially flying along warehouse racks to scan unit labels such as barcodes or QR codes. The collected data is processed in a ground station, creating links between the data and the uploaded warehouse topology to generate comprehensive inventory reports. These reports are ready for XML import or EDI transmission to customers’ ERP systems, ensuring seamless integration and real-time inventory tracking. This technology has been successfully implemented by industry leaders like PepsiCo, FM Logistics, and Kimberly-Clark, enhancing their operational efficiency and safety

Features

| Feature | Description |

|---|---|

| Li-ion Battery | Equipped with high-capacity lithium-ion batteries for extended flight times. |

| Error-Proofing System | Integrated systems to minimize errors during inventory counts. |

| Adaptability | Capable of operating in both narrow and wide aisles, ensuring versatility across warehouse layouts. |

| Anti-Collision System | Advanced sensors to prevent collisions, ensuring safe operations within the warehouse. |

| ERP Integration | Provides inventory results in XML reports or integrates directly with ERP systems for seamless data management. |

| Scalability | Supports an unlimited number of drones operating simultaneously on-site, allowing for scalability based on warehouse size. |

| High-Resolution Imaging | Captures high-resolution images for accurate analysis and verification. |

| All-Weather Operation | Designed to function effectively in various weather conditions, ensuring reliability. |

Use Cases

Improving Operational Efficiency and Safety

UVL Robotics’ inventory drones are ideal for managing extensive warehouse spaces with tens of thousands of pallets. These drones enable seamless inventory management, significantly reducing the time required for stock-taking and addressing health and safety concerns by minimizing human involvement in potentially hazardous tasks.

Automating Inventory Management

By automating inventory processes, these drones allow businesses to reallocate tasks to employees, enhancing workforce productivity. The transition to automated systems reduces costs, improves workplace safety, and supports sustainable operational practices.

Accelerating Inventory Processes

In warehouses spanning thousands of square meters, manual inventory can take several days to complete. UVL Robotics’ AI-powered drones streamline this process, condensing it to less than a day. This acceleration not only improves efficiency but also safeguards employees’ health by minimizing exposure to risks, ensuring business continuity in challenging situations.

How does it work?

Step 1: Order Initialization

An order is created to begin the inventory process.

Step 2: Warehouse Layout Upload

The warehouse topology is uploaded for accurate data mapping.

Step 3: Drone Scanning

Drones navigate racks and scan barcodes or QR codes.

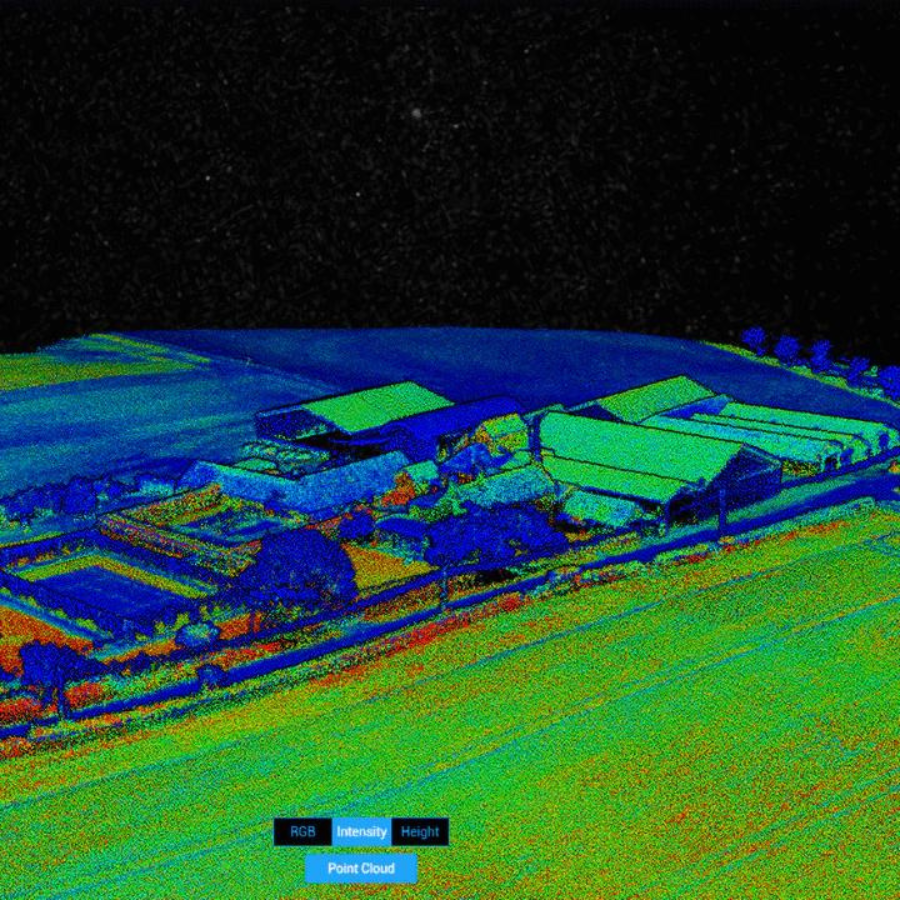

Data Processing

Scanned data, images, and videos are processed at the ground station.

Inventory Report

The system links data to the layout, generating a report ready for XML or EDI integration with ERP systems.

Specifications

| Parameter | Details |

|---|---|

| Scanned Pallets per Battery | 300-750 pcs |

| Time per Scan | 2-5 seconds |

| Flight Duration | 25 minutes |

| Battery Replacement Time | 7-10 seconds |

| Number of Drones per Site | Unlimited |

There are no reviews yet.